Have you ever wondered about the critical role vacuum solenoid valves play in various industries? These devices are essential for controlling the flow of air or fluids in applications ranging from automotive systems to industrial machinery. Learning about their functionality can greatly enhance your understanding of fluid control systems and their importance in modern engineering.

In the fast-paced world of technology and engineering, achieving precision and efficiency is crucial. Vacuum solenoid valves provide a reliable solution by ensuring the controlled movement of fluids or gases, making them indispensable in modern systems. This guide will explore the intricate workings of these valves, their significance across industries, and offer practical tips for their maintenance.

Whether you are a hobbyist, an engineer, or simply someone interested in how things work, this article is designed to give you a thorough understanding of vacuum solenoid valves. We will delve into their functions, types, applications, and maintenance, helping you make informed decisions when working with these components.

Read also:Exploring The Inspiring Journey Of S Camilla Araujo A Global Fashion Icon

Table of Contents

- Introduction to Vacuum Solenoid Valves

- How Does a Vacuum Solenoid Valve Work?

- Types of Vacuum Solenoid Valves

- Common Applications of Vacuum Solenoid Valves

- Benefits of Using Vacuum Solenoid Valves

- Troubleshooting Vacuum Solenoid Valve Issues

- Maintenance Tips for Vacuum Solenoid Valves

- Industries Where Vacuum Solenoid Valves Are Used

- Cost and Lifetime of Vacuum Solenoid Valves

- Conclusion and Next Steps

Exploring Vacuum Solenoid Valves: The Backbone of Fluid Control Systems

Vacuum solenoid valves are essential components in fluid control systems that regulate the flow of gases or liquids. These valves operate by utilizing an electromagnetic coil to open or close a pathway, thereby allowing or preventing the passage of substances through pipelines. Due to their reliability and precision, vacuum solenoid valves are extensively used in automotive, manufacturing, and HVAC systems.

Key Features of Vacuum Solenoid Valves

Vacuum solenoid valves are known for several standout features that make them indispensable in a variety of applications:

- Exceptionally durable and long-lasting design, ensuring consistent performance over time.

- Precision control over the flow of fluids or gases, providing optimal accuracy in diverse environments.

- Compact size, making installation easy and efficient, even in tight spaces.

- Compatibility with various media, including air, water, and oil, making them versatile for different applications.

These features collectively contribute to the efficiency and safety of vacuum solenoid valves, making them ideal for use in numerous industries and settings.

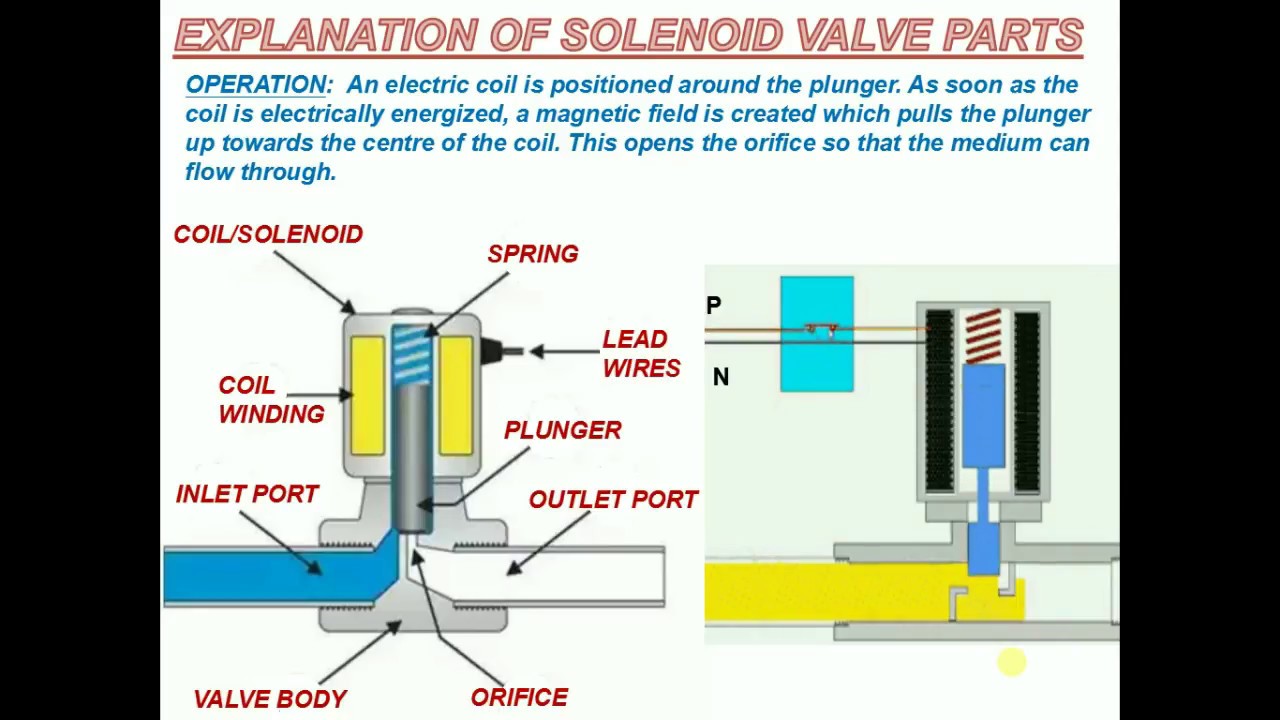

The Mechanism Behind Vacuum Solenoid Valves: How They Operate

The operation of a vacuum solenoid valve combines simplicity with sophistication. When an electric current passes through the solenoid coil, it generates a magnetic field that moves a plunger, which in turn opens or closes the valve. This mechanism allows for precise control over the flow of substances, ensuring optimal performance in various systems.

Components of a Vacuum Solenoid Valve

To fully understand how a vacuum solenoid valve functions, it's important to familiarize yourself with its key components:

- Solenoid Coil: The electromagnetic coil that generates the magnetic field necessary for valve operation.

- Plunger: The movable part that physically opens or closes the valve, controlling the flow of substances.

- Valve Body: The housing that contains the valve mechanism, ensuring stability and durability.

- Seal: A critical component that prevents leakage when the valve is closed, maintaining system integrity.

Each of these components works in harmony to ensure the reliability and efficiency of the vacuum solenoid valve, making it a cornerstone of fluid control systems.

Read also:Discover The Timeless Beauty And History Of The Alamo Through Stunning Imagery

Different Types of Vacuum Solenoid Valves and Their Applications

Vacuum solenoid valves come in a variety of types, each tailored for specific applications. Understanding the differences between these types can help you select the most appropriate valve for your needs:

Direct Acting Valves

Direct acting vacuum solenoid valves use the electromagnetic force directly to open or close the valve. They are particularly suitable for low-pressure applications and are known for their quick response times, making them ideal for scenarios requiring rapid adjustments.

Pilot Operated Valves

Pilot operated valves combine electromagnetic force with system pressure to operate. These valves are designed for high-pressure applications and offer greater flow capacity compared to direct acting valves, making them suitable for demanding industrial environments.

Where Are Vacuum Solenoid Valves Used? Exploring Their Applications

Vacuum solenoid valves are widely used across various industries, playing a pivotal role in ensuring smooth and efficient operations. Some common applications include:

Automotive Industry

Within the automotive sector, vacuum solenoid valves are instrumental in controlling the flow of air in engines. This helps regulate emissions, enhance fuel efficiency, and contribute to overall vehicle performance.

Manufacturing Sector

In manufacturing plants, vacuum solenoid valves are employed to manage the flow of fluids in production lines. Their precision and reliability ensure that manufacturing processes run smoothly, minimizing downtime and maximizing productivity.

Why Choose Vacuum Solenoid Valves? Exploring the Advantages

There are numerous benefits to incorporating vacuum solenoid valves into your systems:

Increased Efficiency

Vacuum solenoid valves provide unparalleled control over fluid flow, leading to increased efficiency and reduced energy consumption. This makes them a cost-effective solution for businesses looking to optimize their operations.

Enhanced Safety

By ensuring precise control of substances, vacuum solenoid valves help prevent leaks and accidents, thereby enhancing overall safety in both industrial and everyday applications.

Addressing Common Issues with Vacuum Solenoid Valves

Like any mechanical component, vacuum solenoid valves can encounter issues over time. Some common problems include:

- Leakage caused by worn-out seals, which can compromise system performance.

- Failure to open or close properly, often due to mechanical wear or electrical faults.

- Electrical faults in the solenoid coil, which can disrupt the valve's operation.

Regular maintenance and inspections are crucial for identifying and resolving these issues before they escalate, ensuring the longevity and reliability of the valve.

Maximizing Valve Lifespan: Maintenance Tips for Vacuum Solenoid Valves

To ensure your vacuum solenoid valves perform optimally and last as long as possible, consider the following maintenance tips:

Regular Inspections

Conduct routine inspections to identify signs of wear and tear, such as leaks or corrosion. Early detection can prevent minor issues from becoming major problems.

Cleaning and Lubrication

Keep the valve components clean and well-lubricated to minimize friction and ensure smooth operation. Proper maintenance practices can significantly extend the lifespan of your vacuum solenoid valves.

Vacuum Solenoid Valves Across Industries: Where They Make a Difference

Vacuum solenoid valves are indispensable in several industries, contributing to the efficiency and safety of various systems:

Healthcare Sector

In the healthcare industry, vacuum solenoid valves are used in medical equipment to control the flow of gases. This ensures the safe and accurate delivery of substances in applications such as ventilators and anesthesia machines, where precision is critical.

Food and Beverage Industry

The food and beverage industry relies heavily on vacuum solenoid valves for precise control over the flow of liquids in processing and packaging systems. Their reliability and compatibility with various media make them essential for maintaining hygiene and quality standards.

Understanding the Cost and Lifespan of Vacuum Solenoid Valves

The cost of vacuum solenoid valves varies depending on factors such as size, material, and specific application requirements. On average, they can range from $20 to several hundred dollars. With proper maintenance, these valves can last anywhere from 5 to 10 years, providing reliable performance throughout their lifespan.

Wrapping Up: The Importance of Vacuum Solenoid Valves

In conclusion, vacuum solenoid valves are critical components in controlling the flow of fluids and gases in various systems. Their precision, reliability, and versatility make them indispensable in numerous industries. By understanding their function, types, and applications, you can make informed decisions when selecting and maintaining these essential components.

We invite you to share your thoughts and experiences with vacuum solenoid valves in the comments section below. Additionally, feel free to explore other articles on our website for more insights into engineering and technology topics. Together, let's continue expanding our knowledge and appreciation of these vital components!

Data sources: Engineering Toolbox, Industrial Equipment.