In industrial applications, selecting the appropriate valve can greatly enhance efficiency, reliability, and cost-effectiveness. Two of the most widely used valve types are ball valves and gate valves. To make an informed decision, it's essential to understand their differences and applications.

Ball valves and gate valves both play a critical role in controlling fluid flow within pipelines. Despite serving the same primary purpose, these valves operate differently and are suited for distinct scenarios. Whether you're working on plumbing systems, oil and gas pipelines, or water treatment plants, choosing the right valve can significantly improve your system's performance.

This in-depth guide will explore the features, advantages, disadvantages, and applications of ball valves and gate valves. By the end of this article, you'll have a thorough understanding of which valve type best suits your needs, ensuring optimal functionality and longevity in your operations.

Read also:Mastering Wire Voltage Testing A Comprehensive Guide

Table of Contents

- Introduction to Valves

- What is a Ball Valve?

- What is a Gate Valve?

- Comparison of Ball and Gate Valves

- Applications of Ball Valves

- Applications of Gate Valves

- Choosing the Right Valve

- Advantages and Disadvantages

- Maintenance and Lifespan

- Cost Considerations

An Overview of Valves in Industrial Applications

Valves are indispensable components in fluid control systems, regulating the flow of liquids, gases, and other substances. They are employed across various industries, ranging from residential plumbing to heavy industrial operations. The type of valve chosen depends on factors such as the nature of the fluid, pressure requirements, and operational conditions.

Among the numerous types of valves available, ball valves and gate valves stand out as two of the most popular options. Each type possesses unique characteristics that make it suitable for specific applications. Gaining a deeper understanding of these differences is essential for ensuring efficient and reliable system performance.

Exploring Ball Valves: Functionality and Features

A ball valve is a type of rotational motion valve that utilizes a ball to control or halt fluid flow. The ball contains a hole, or port, through its center, which allows fluid to pass when aligned with the pipeline. Rotating the ball by 90 degrees blocks the flow entirely.

Key Features of Ball Valves

- Compact design, making it suitable for installations in confined spaces.

- Quick and effortless operation with a simple quarter-turn mechanism.

- Superior sealing capabilities, minimizing the risk of leaks.

- Capable of withstanding high-pressure and high-temperature conditions.

Ball valves are frequently employed in applications requiring rapid shut-off and reliable performance. Their availability in various sizes and materials enhances their versatility across different industries.

Understanding Gate Valves: Design and Functionality

A gate valve, also referred to as a sluice valve, is a linear motion valve that controls flow by raising or lowering a wedge or gate. It provides a straight-through flow path, reducing pressure drop and turbulence in the pipeline.

Key Features of Gate Valves

- Designed primarily for on/off service rather than throttling applications.

- Offers a clear flow path with minimal resistance, ensuring smooth fluid passage.

- Ideal for larger pipe sizes and lower pressure applications.

- Operates more slowly compared to ball valves, making it suitable for scenarios where rapid response is unnecessary.

Gate valves are commonly used in applications where full flow is required and frequent operation is not necessary. They are extensively utilized in water supply systems, oil pipelines, and chemical processing plants.

Read also:How To Effectively Remove Lip Balm Stains From Clothes

A Detailed Comparison of Ball and Gate Valves

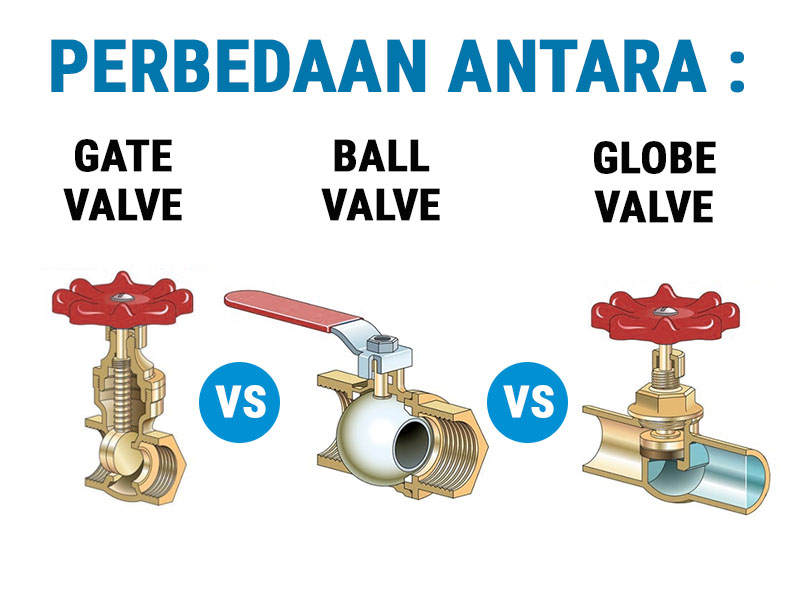

Although both ball valves and gate valves control fluid flow, they differ significantly in several aspects. Below is a comprehensive comparison:

Operational Mechanism

Ball valves function with a quarter-turn mechanism, enabling quick and efficient shut-off. Conversely, gate valves rely on linear motion, requiring multiple turns to fully open or close. This characteristic makes ball valves more suitable for applications demanding rapid response.

Flow Characteristics

Gate valves provide a straight-through flow path, minimizing pressure loss and turbulence. On the other hand, ball valves have a slightly restricted flow path due to the ball's design but offer exceptional sealing capabilities.

Material and Durability

Ball valves are typically constructed from materials like stainless steel, brass, and PVC, ensuring durability and resistance to corrosion. Gate valves, on the other hand, are often made from cast iron, bronze, or carbon steel, providing robustness for heavy-duty applications.

Key Applications of Ball Valves

Ball valves are extensively used across various industries due to their versatility and reliability. Some of their most common applications include:

- Oil and gas pipelines, where they are employed to control high-pressure flows.

- Chemical processing plants, where they handle corrosive substances effectively.

- Residential plumbing systems, where they enable the rapid shut-off of water supply.

- Cryogenic applications, where low-temperature performance is crucial.

According to a report by MarketsandMarkets, the global ball valve market is projected to experience significant growth, driven by increasing demand in the oil and gas sector.

Primary Applications of Gate Valves

Gate valves are favored in situations where full flow and minimal pressure drop are required. Their typical applications include:

- Water supply systems for municipalities and industrial plants.

- Petroleum pipelines for transporting crude oil and refined products.

- Power generation facilities for managing steam and water flow.

- Chemical processing industries for bulk material handling.

A study by Grand View Research emphasizes the rising adoption of gate valves in water management projects, especially in developing countries.

Factors to Consider When Selecting the Right Valve

Selecting the appropriate valve for your specific application involves evaluating several factors:

Flow Requirements

If your application demands full flow with minimal pressure loss, a gate valve is the better option. Conversely, for scenarios requiring rapid shut-off, a ball valve proves more suitable.

Operating Conditions

Ball valves excel in high-pressure and high-temperature environments, whereas gate valves are ideal for larger pipe sizes and lower pressure applications.

Maintenance Needs

Ball valves generally require less maintenance due to their straightforward design and fewer moving parts. In contrast, gate valves, with their more intricate mechanisms, may necessitate regular servicing to maintain optimal performance.

Exploring the Strengths and Limitations of Ball and Gate Valves

Both ball valves and gate valves possess distinct advantages and limitations:

Advantages of Ball Valves

- Quick and effortless operation, ensuring convenience.

- Exceptional sealing capabilities, minimizing the risk of leaks.

- Compact design, enabling space-saving installations.

Disadvantages of Ball Valves

- Not suitable for throttling applications, limiting their versatility.

- Potential wear over time in abrasive fluid environments, affecting longevity.

Advantages of Gate Valves

- Provides full flow with minimal resistance, ensuring efficient fluid passage.

- Available in large sizes, making them ideal for high-capacity applications.

Disadvantages of Gate Valves

- Slower operation compared to ball valves, which may be a disadvantage in certain scenarios.

- Potentially prone to leakage if not properly maintained, requiring regular attention.

Maintaining and Extending the Lifespan of Valves

Regular maintenance is essential for maximizing the lifespan of both ball and gate valves. Key maintenance tasks include:

- Inspection for signs of wear and tear, ensuring early detection of issues.

- Lubrication of moving parts to ensure smooth operation and prevent corrosion.

- Cleaning and replacement of seals as needed to maintain optimal performance.

With proper care, ball valves can last up to 20 years, while gate valves may have a lifespan ranging from 15 to 25 years, depending on operating conditions.

Evaluating the Cost Implications of Ball and Gate Valves

The cost of ball valves and gate valves varies based on size, material, and application. Typically, ball valves are more cost-effective for smaller sizes, while gate valves become more economical for larger pipe diameters. It's crucial to consider the total cost of ownership, including installation, maintenance, and replacement expenses, to make a well-informed decision.

Conclusion

In summary, both ball valves and gate valves offer unique advantages and are suited to specific applications. Ball valves are ideal for rapid shut-off and high-pressure environments, while gate valves are better suited for full flow and larger pipe sizes. By understanding the specific requirements of your application, you can make an informed decision that enhances system efficiency and reliability.

We invite you to share your thoughts and experiences in the comments section below. Additionally, explore our other articles for further insights into industrial equipment and technologies. Together, let's optimize system performance and reliability!